Insul-Deck

Insul-Deck

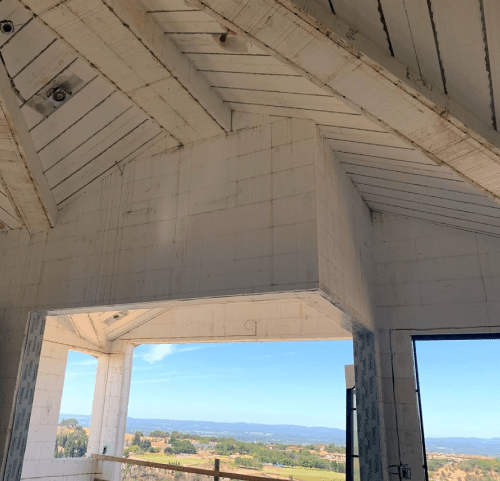

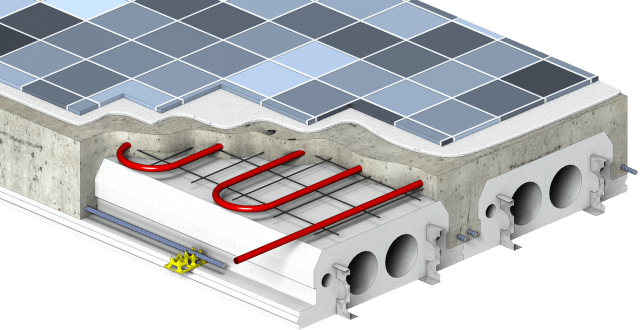

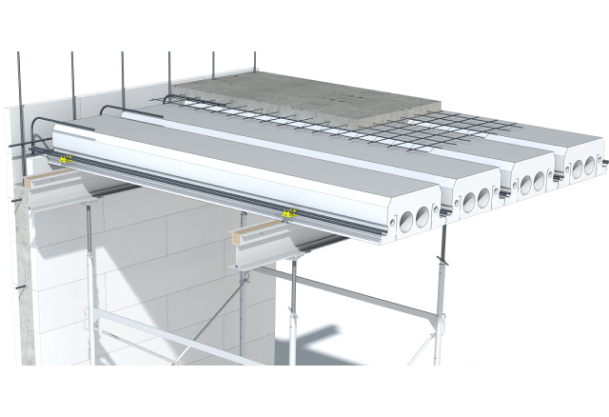

Stay in place insulating concrete forms made of Expanded Polystyrene (EPS). Integrated steel beams are molded into each Insul-Deck panel creating formwork for the support of concrete, reinforcement, and construction loads with minimal shoring. are steel-reinforced, foamed plastic in sulation boards used as permanent, stay-in-place concrete formwork for floor and roof construction. Reinforced concrete joists are spaced at 24″ [610mm] on center and poured monolithi- cally with the slab to form a T-Beam rein forced concrete structure.

Insul-Deck Panels

Product Information:

- Overview of Spans, Shoring, Insulation Values and other properties

- Installation Checklist

Builders and Developers

INSUL-DECK saves on labor (MHR of 0.04-0.06 are common) and uses upto 50% less concrete & 33% less steel compared to traditional concrete slabs. And by reducing the mass of the structure, costs for supporting elements are lower.

Step #1: Setup Shoring and Insul-Deck

Step #2: Install Rebar and Pour Concrete

Step #3: Remove Shoring

Architects & Engineers

it is adaptable for any project

• Floors forms one-way suspended CIP concrete slab

• Roofs forms are structurally superior

• Elevated Buildings where flood waters are a concern

• Tilt-Up Designed to be the fastest method available for

building a concrete tilt-up structure